Many people may have a popular understanding of sugar in that the substance fills virtually every sweet confection on the planet. But the truth of the matter is that sugar has occurred naturally in certain foods since the dawn of agriculture. There can be some confusion because naturally occurring sugars bear no similarity or potency to the refined products that are used constantly today.

Sugar has existed since the dawn of civilization in both fruits and other substances like honey. During the Middle Ages, it became an extracted source from naturally-occuring sugar cane stalks that were first discovered in the Pacific and then massively transported around the globe.

But there is much more than meets the eye when it comes to a full and comprehensive history of this sweet stuff. Even the white, refined product we know today has a long history that dates back to the first discovery of sugar cane. In this comprehensive guide, we are going to take a deep dive into the complete history of sugar. We will also look at how it is made today in a step-by-step process.

Where Does Sugar Come From?

Although not a drug per se, sugar is so satisfying that it is not far off from the effects of caffeine or even nicotine. Although there are health risks to high consumption, it is such a part of the human diet now that many do not even ponder where it came from.

But sugar has a long and varied history throughout the human story, and apart from fruits and honeys, sugar as we know it originated in New Guinea roughly 10,000 years ago.

New Guinea sugarcane during the BCE Era was never truly cultivated during this time; New Guineas simply cut the cane and chewed and sucked on the sap for a sweet fix after a meal–kind of like an ancient incarnation of dessert.

From this time and up until around 600 CE, primitive forms of sugar cultivation occurred across Asia, although little is known about what form this cultivation took on. But what has been recorded is that sugarcane was actively crystallized during this time in either India, Greece, or the Roman Empire.

Therefore, sugar as we know it today in its crystallized form is roughly 2,000 years old.

With this in mind, there are indeed records of knowledge of sugar among the ancient Greeks and Romans, but only as an imported medicine, and not as a food. During the medieval era, Arab entrepreneurs adopted sugar production techniques from India and expanded the industry.

Medieval Arabs in some cases set up large plantations equipped with on-site sugar mills or refineries, which is how sugarcane cultivation would continue well into the 20th century. The cane sugar plant, which is native to a tropical climate, requires both a lot of water and a lot of heat to thrive, and therefore, the cultivation of the plant spread throughout the medieval Arab world using artificial irrigation.

Sugar cane was first grown extensively (as a major crop for commerce) in medieval Southern Europe during the period of Arab rule in Sicily beginning around the 9th century CE. In addition to Sicily, Al-Andalus (in what is currently southern Spain) was an important center of sugar production, beginning by the tenth century.

From the Arab world, sugar was exported throughout Europe. The volume of imports increased in the later medieval centuries as indicated by the increasing references to sugar consumption in late medieval Western writings. But cane sugar remained an expensive import.

In fact, its price per pound in 14th and 15th century England was about equally as high as imported spices from tropical Asia such as mace (nutmeg), ginger, cloves, and pepper, which had to be transported across the Indian Ocean in that era.

By the time of the Age of Empires in the 19th and 20th centuries, sugar refineries started to become widespread, and having first been discovered during the eighteenth century, sugar beet became the easiest and cheapest form of extraction until the age of mass sugar consumption that started in the mid-20th century onwards.

What Is Sugar Made Out Of?

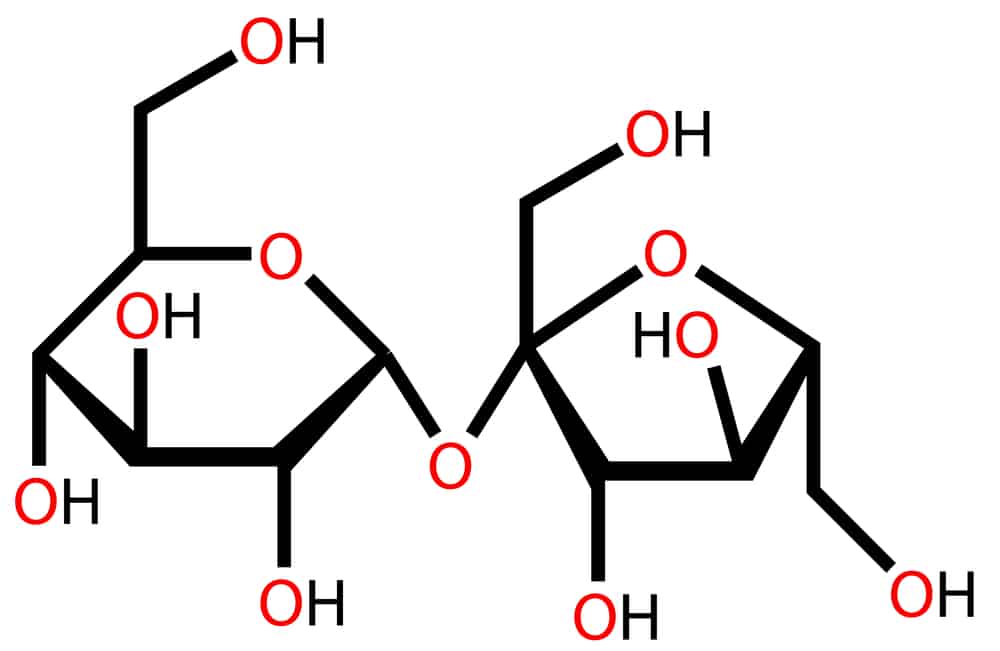

At its most basic, scientific form, sugar is made up of a molecule known as sucrose. Sucrose is a molecule composed of 12 atoms of carbon, 22 atoms of hydrogen, and 11 atoms of oxygen.

Like all compounds made from these three elements, sugar is a carbohydrate. It’s found naturally in most plants, and this is known as “natural sugars,” but especially in sugarcane and sugar beets—hence their names.

Sucrose is actually two simpler sugars stuck together: fructose and glucose. In recipes, a little bit of acid (for example, some lemon juice or cream of tartar) will cause sucrose to break down into these two components. If you look closely at dry sugar, you’ll notice it comes in little cubelike shapes. These are sugar crystals, orderly arrangements of sucrose molecules.

When you add sugar to water, the crystals dissolve and go into solution. But you can’t dissolve an infinite amount of sugar into a fixed volume of water. When as much sugar has been dissolved into a solution as possible, the solution is said to be saturated. The saturation point is different at different temperatures. The higher the temperature, the more sugar that can be held in solution.

For example, when you cook up a batch of candy, you cook sugar, water, and various other ingredients to extremely high temperatures. At these high temperatures, the sugar remains in solution, even though much of the water has boiled away. But when the candy is through cooking and begins to cool, there is more sugar in solution than is normally possible. The solution is said to be supersaturated with sugar.

Supersaturation is an unstable state. The sugar molecules will begin to crystallize back into a solid at the least provocation. Stirring or jostling of any kind can cause the sugar to begin crystallizing.

How Sugar Manifests in Various Sweets

The fact that sugar solidifies into crystals is extremely important in candy making. There are basically two categories of candies – crystalline (candies which contain crystals in their finished form, such as fudge and fondant), and noncrystalline, or amorphous (candies which do not contain crystals, such as lollipops, taffy, and caramels).

Recipe ingredients and procedures for noncrystalline candies are specifically designed to prevent the formation of sugar crystals, because they give the resulting candy a grainy texture.

One way to prevent the crystallization of sucrose in candy is to make sure that there are other types of sugar—usually, fructose and glucose—to get in the way. Large crystals of sucrose have a harder time forming when molecules of fructose and glucose are around.

Crystals form something like Legos locking together, except that instead of Lego pieces, there are molecules. If some of the molecules are a different size and shape, they won’t fit together, and a crystal doesn’t form.

A simple way to get other types of sugar into the mix is to “invert” the sucrose (the basic white sugar you know well) by adding an acid to the recipe. Acids such as lemon juice or cream of tartar cause sucrose to break up (or invert) into its two simpler components, fructose and glucose. Another way is to add a non sucrose option, such as corn syrup, which is mainly glucose.

In fact, some lollipop recipes use as much as 50% corn syrup; this is to prevent crystals from ruining the texture.

Fats in candy serve a similar purpose. Fatty ingredients such as butter help interfere with crystallization—again, by getting in the way of the sucrose molecules that are trying to lock together into crystals. Toffee owes its smooth texture and easy breakability to an absence of crystals, thanks to a large amount of butter in the mix.

Where In The U.S. Is Sugar Cane Grown?

In the United States, sugarcane is a crop that mostly grows in humid, preferably tropical conditions. Louisiana, Florida, and Texas are the three U.S. states that produce, harvest, and manufacture sugarcane for American consumption.

There is also a smaller manufacturing presence for sugarcane in Hawaii as well. Sugarcane production is big business in the United States, and cane for sugar was 35.5 million tons in 2020 alone. In 2019, cane for sugar was valued at more than $1.2 billion.

Florida is the top producing state, and has produced more than 17.5 million tons of sugarcane for sugar in 2020. That same year, Louisiana produced more than 15 million tons of sugarcane. Texas also produces more than 1.1 million tons annually.

U.S. Sugarcane Statistics

After peaking in 1972 at 102 pounds per person, the use of sugar (both cane and beet) in domestic food and beverage industries had declined to a low of 60 pounds per person by 1986. In following years, per person use by these industries fluctuated between 61 and 66 pounds. By 2016, according to USDA sources, Americans consumed 69.7 pounds of refined sugar per person.

In contrast, Americans consumed 41.4 pounds of corn-derived sweeteners and various derivatives. Even though many of us like to think we keep our consumption in check, it is quite a difficult thing to do since sugar saturates virtually everything.

Deliveries to food manufacturers generally constitute a major portion of refined deliveries. Of those industries, baking and cereal industries are generally the largest end users, followed by confectionery makers.

The number of sugarcane mills has steadily declined. In 2005, 21 cane millers remained in business, with a combined milling capacity of 293,930 tons daily. With 13 mills, Louisiana had a daily milling capacity of 164,630 tons. Florida had five operating mills, Hawaii had two mills and Texas had one.

As of 2005, eight sugarcane refineries operated in the United States, dominated by the Domino Sugar Corporation and the Imperial Sugar Company. Dominos’ three plants are located in Louisiana, Maryland and New York. Imperial operates plants in Georgia and in Louisiana. Florida’s sugarcane is refined by two companies: U.S. Sugar and Florida Crystals Corporation.

The other refinery, located in California, is C&H, which has the largest capacity of any U.S. sugarcane refinery. It can process 3,400 tons of raw product each day. Four refineries have closed in the last decade. Thirty years ago, there were over twenty in operation.

Although still a large commodity in the U.S, there is growing space for safe substitutes and a greater need to lessen consumption throughout the 21st century so far.

Why Do They Burn Sugar Cane Fields?

Although the burning of sugarcane fields is falling out of favor in the 21st century due to the local environmental concerns surrounding the burn sight, the practice is still performed by some manufacturers.

The practice of burning sugarcane fields has been largely discontinued throughout the world because of concerns about air pollution, but farmers still do it in Florida’s main producing region known as the Glades. Producers there say continuing the traditional practice is necessary to prevent harvesting accidents and keep costs down.

Burning requires a permit, and at least in theory, farmers are not allowed to burn on days when the smoke will drift in certain directions. But despite regulations, residents around cane fields complain that smoke often impacts sensitive areas like schools and hospitals. On burning days in the fall and winter, the air fills with ash the residents refer to as “black snow.”

For communities in the Everglades, cane season means an increase in asthma attacks, sinus issues and other breathing problems. Local health care providers are also well aware of the effects of the “black snow” and see a 35 percent uptick in respiratory-related hospital visits when cane is burning.

Older residents report chronic breathing trouble and chest pain, and there’s mounting evidence that exposure to burning sugarcane fields can cause other long-term health problems. Researchers have also found that sugarcane burning is responsible for significant quantities of cancer-causing pollutants, like formaldehyde, in the air and that residents in the Everglades breathe in more of these chemicals than the rest of the state.

Despite complaints from locals and years of their own evidence, however, the local health departments have largely ignored the burning at the behest of industry representatives.

The sugarcane industry insists it complies with Clean Air Act standards and that federal monitoring says the Everglades have higher air quality than average. Technically, this is correct, but only because of a measurement loophole.

Issues That Arise From Burning Sugarcane Fields

Compliance with the Clean Air Act is determined by the 24-hour average of particulate matter in the air, but because individual cane fields don’t burn very long, pollution from the burning fields happens in quick episodes.

So while the average amount of pollution detected over a 24-hour period might not be enough to trigger federal regulators to take action, ash and smoke may spike in short, intense episodes that are enough to set off asthma attacks and other problems. This is of particular concern because the amount of fine particulate matter in the air could be up to four times higher than the average, more than enough to cause respiratory distress.

In Florida, residents have made attempts to challenge the burning, but it hasn’t been easy. For starters, many feel a sense of conflict about taking on the powerful industry, as it’s one of the main employers in the area.

So although burning sugarcane is a common practice that aids in the breaking down of sugarcane, the environmental impacts are of particular concern with this practice.

Does All Sugar Come From Sugar Cane?

White table sugar comes from either sugarcane or sugar beets and is usually sold without its plant source clearly identified. This is because—chemically speaking—the two products are identical. Refined table sugar is pure, crystallized sucrose, much in the same way that pure salt is simply sodium chloride. Sucrose is found naturally in honey, dates, and sugar maple sap, but it is most concentrated in sugarcane and sugar beets.

The refining process renders the original plant irrelevant as the sucrose is completely extracted from the plant that produced it.

However, distinguishing between cane and beet sugar is not completely a marketing ploy and is fairly common on sugars sold in health food stores. In order to make sugarcane crystals pure white, the sugar is usually processed with bone char; beet sugar does not require this step.

Although the final sugarcane product does not have bone in it, this distinction is important to many vegans (more on this below) and other vegetarians who seek to minimize animal suffering.

Additionally, many bakers and pastry chefs claim there is a difference between brown sugars made from sugarcane and those of sugar beets. The molasses that colors brown sugar comes from sugarcane processing and is not a high-grade product of sugar beets. Thus, brown sugar made from sugar beets has sugarcane molasses added.

Although the industry maintains that they are identical products, many chefs use only brown sugar made from sugarcane, maintaining that brown beet sugar negatively affects their products. Although some assert that the difference lies in the trace minerals from the two plants, it is more likely that there is a moisture difference that may affect baked goods and other desserts.

How Is Sugar Made Step By Step?

The process of separating sugar from the sugarcane plant is accomplished through two steps: mill crushing and refinery extraction. Sugarcane is initially processed into raw product at mills near the cane fields. Because cane is bulky and relatively expensive to transport, it must be processed as soon as possible to minimize deterioration.

The raw material is then shipped to refineries to produce refined sugar. The final products of refining include three types: powdered, granulated and brown (the latter of which contains some molasses).

Sugarcane requires an average temperature of 75 degrees Fahrenheit (23.9 degrees

Celsius) and uniform rainfall of about 80 inches (203 centimeters) per year. So this is why it is grown in tropical or subtropical areas.

Sugarcane takes about seven months to mature in a tropical area and about 12-22 months in a subtropical area. At this time, fields of sugarcane are tested for sucrose, and the most mature fields are harvested first. In Florida, Hawaii, and Texas, standing cane is fired to burn off the dry leaves. In Louisiana, the six- to ten-feet (1.8- to 3-meter) tall cane stalks are cut down and laid on the ground before burning.

Here in the United States, harvesting (of both cane and beet) is done primarily by machine, although in some states it is also done by hand. The harvested cane stalks are loaded mechanically into trucks or railroad cars and taken to mills for processing into raw product.

Processing

After the cane arrives at the mill yards, it is mechanically unloaded, and excessive soil and rocks are removed. The cane is cleaned by flooding the carrier with warm water (in the case of sparse rock and trash clutter) or by spreading the cane on agitating conveyors that pass through strong jets of water and combing drums (to remove larger amounts of rocks, trash, and leaves, etc.). At this point, the cane is clean and ready to be milled.

When the beets are delivered at the refinery, they are first washed and then cut into strips. Next, they are put into diffusion cells with two or three heavily grooved crusher rollers to break the cane and extract a large part of the juice, or swing-hammer type shredders (1,200 RPM) shred the cane without extracting the juice.

Revolving knives cutting the stalks into chips are supplementary to the crushers. (In most countries, the shredder precedes the crusher.) A combination of two, or even all three, methods may be used. The pressing process involves crushing the stalks between the heavy and grooved metal rollers to separate the fiber (bagasse) from the juice that contains the sugar.

As the cane is crushed, hot water (or a combination of hot water and recovered impure juice) is sprayed onto the crushed cane counter as it leaves each mill for diluting. The extracted juice, called vesou, contains 95 percent or more of the sucrose present. The mass is then diffused, a process that involves finely cutting or shredding the stalks. Next, the sugar is separated from the cut stalks by dissolving it in hot water or hot juice.

Purification

The juice from the mills, a dark green color, is acidic and turbid. The clarification (or defecation) process is designed to remove both soluble and insoluble impurities (such as sand, soil, and ground rock) that have not been removed by preliminary screening. The process employs lime and heat as the clarifying agents. Milk of lime (about one pound per ton of cane) neutralizes the natural acidity of the juice, forming insoluble lime salts.

Heating the lime juice to boiling coagulates the albumin and some of the fats, waxes, and gums, and the precipitate formed entraps suspended solids as well as the minute particles.

The sugar beet solution, on the other hand, is purified by precipitating calcium carbonate, calcium sulfite, or both in it repeatedly.

Impurities become entangled in the growing crystals of precipitate and are removed by continuous filtration.

The muds separate from the clear juice through sedimentation. The non-sugar impurities are removed by continuous filtration. The final clarified juice contains about 85 percent water and has the same composition as the raw extracted juice except for the removed impurities.

To concentrate this clarified juice, about two-thirds of the water is removed through vacuum evaporation. Generally, four vacuum-boiling cells or bodies are arranged in series so that each succeeding body has a higher vacuum (and therefore boils at a lower temperature). The vapors from one body can thus boil the juice in the next one—the steam introduced into the first cell does what is called multiple-effect evaporation.

The vapor from the last cell goes to a condenser. The syrup leaves the last body continuously with about 65 percent solids and 35 percent water.

The sugar beet sucrose solution, at this point, is also nearly colorless, and it likewise undergoes multiple-effect vacuum evaporation. The syrup is seeded, cooled, and put in a centrifuge machine. The finished beet crystals are washed with water and dried.

Crystallization Process

Crystallization is the next step in the manufacturing process. Crystallization takes place in a single-stage vacuum pan. The syrup is evaporated until saturated. As soon as the saturation point has been exceeded, small grains of sugar are added to the pan, or “strike.” These small grains, called seed, serve as nuclei for the formation of sugar crystals.

Additional syrup is added to the strike and evaporated so that the original crystals that were formed are allowed to grow in size.

The growth of the crystals continues until the pan is full. When sucrose concentration reaches the desired level, the dense mixture of syrup and crystals, called massecuite, is discharged into large containers known as crystallizers. Crystallization continues in the crystallizers as the massecuite is slowly stirred and cooled.

Massecuite from the mixers is allowed to flow into centrifugals, where the thick syrup, or molasses, is separated from the raw product by centrifugal force.

After this intensive process, the product is ready to be packaged and shipped by manufacturers.

Is Sugar Vegan?

Although derived from a plant, there are some issues with its processing that make it non-vegan friendly.

As mentioned, bone char—often referred to as natural carbon—is widely used by the industry as a decolorizing filter, which allows the sugar cane to achieve a white color. Bone char is made from the bones of cattle who were slaughtered in foreign countries and sold to traders in other foreign countries, who then sell the bones back to the U.S. sugar industry.

Typically, sugar is made from sugarcane, sugar beets, or coconuts. Beet and coconut sugar are never processed with bone char, so those are excellent ways to maintain a vegan lifestyle with sugar.

Is Sugar a GMO?

In terms of sugar that is derived from sugarcane, GMOs are not present. But there are some GMO concerns with sugar beets.

One of the main pain points in any horticultural operation is weed control. Weeds reduce farm and forest productivity, they invade crops, smother pastures and in some cases can harm livestock. They aggressively compete for water, nutrients and sunlight, resulting in reduced crop yield and poor crop quality. Having a crop resistant to herbicides helps make weed control much easier and economical to the farmer.

Before the advent of safe herbicides for weed control on crops, weeds had to be controlled manually. This is a major factor contributing to labor costs for the United States Farmer, and this is why efforts were made to provide GMO sugar beets in 2008.

But it is important to point out that whether or not sugar is refined from genetically modified sugar beets, conventional sugar beets or organic cane the result is a disaccharide called sucrose; what we know simply as table sugar. This is because the refining process removes impurities such as color, fibers, odors, proteins and DNA.

What Makes Sugar Organic?

It is a bit confusing when it comes to calling it “organic” because all sugar is organic in its rawest form. Pure, unprocessed organic sugar comes from sugar cane. Natural cane is brimming with vitamins, minerals, enzymes, fibers, and phytonutrients that help the body digest the naturally occurring sugars.

The minerals required to digest sugar are calcium, phosphorus, chromium, magnesium, cobalt, copper, iron, zinc and manganese. It also contains vitamins A, C, B1, B2, B6, niacin, and pantothenic acid, which work synergistically with the minerals to nourish the body.

Polyphenols are also present in natural sugar cane. In simple terms, polyphenols are phytonutrients (nutrients found in plant form) with powerful antioxidant properties and numerous potential health benefits. Sugar cane contains a unique mix of antioxidant polyphenols. The polyphenols, vitamins, and minerals present in sugar cane help slow down the absorption of the sugars and prevent the sharp rise in blood sugar levels.

When you eat any type of sugar that has been refined, your body has to pull stored nutrients from itself to be able to properly digest it. This is commonly called “leaching”. The refined product robs calcium and other minerals from your bones, tissues, and teeth in order to be digested. Since calcium is one of the most abundant minerals in natural sugar cane and needed the most for proper digestion of sugar, it is the most important for your body to retain.

Rapadura is an organic, unrefined sugar with a delicious, caramel flavor and a grainy texture. It is not crystallized, like processed sugars. And unlike white sugar, which is void of any vitamins or minerals, rapadura is actually high in nutrients. It’s very easy to bake with, too.

Rapadura is harvested from sustainable family farms in Brazil through the Hand in Hand, fair trade program.

But the visible differences of organic sugar versus refined sugar are evident by the dark color and coarser texture. Because organic sugar retains all of the nutrients found in its natural state, it also has a prominent molasses aroma. Surprisingly, however, organic doesn’t taste much different than refined. The molasses taste is very minimal.

Why Is Sugar White?

Contrary to popular belief, sugar is naturally white. When the sugar is initially extracted from the plants, it has a golden color because of the non-sugar materials attached to and within the sugar crystals.

This golden sugar is then purified, where these plant fibers and molasses are removed, extracting the sugar molecules from the non-sugar materials and restoring the sugar crystals to their natural white color.

Can We Live Without It?

A certain amount of sugar is required for the human body to maintain a balanced insulin level to support biological processes. But only a small amount–preferably natural kinds–is needed for the human body each day.

In fact, as the recent onslaught of type 1 and 2 diabetes cases across the U.S. in the past few decades showcases, there are some very serious risks that come with excess consumption. Weight gain is one such health concern, but diabetes is a much more serious disease that is rooted in sugar consumption.

You are not going to have any adverse health reactions from the occasional candy bar or regular soda, but excess consumption day-in, day-out is not advised.

Which Country Consumes The Most Sugar?

By far, the United States is the single country on the planet that consumes the most sugar. Here in America, comfort foods rule the day, and even in processed American foods that are advertised as healthy–sugar or its extracts are still found in these items.

Sugar is not just found in sweet treats and drinks; it is almost always used in cooking and the manufacturing of processed foods due to balancing of other ingredients or to add a mildly sweet flavor to even savory foods.

Which Country Produces The Most Sugar?

Due to its tropical climate, Brazil comes in first amongst the world’s countries in terms of sugar production.

Since the mid-1990s, the volume of cane harvested and processed in Brazil has almost tripled. That reflects the rising demand for cane ethanol and renewable fuels in general. With no drop in food production over that time, Brazil has proved its viability as an effective and efficient ethanol powerhouse.

Which State [In The U.S.] Produces The Most Sugar?

Of the four states that produce sugarcane in the United States, Florida’ production has expanded significantly since the United States ceased importing sugar from Cuba in 1960. Florida is the largest cane-producing region in the United States.

This is because most of the sugarcane is produced in organic soils along the southern and southeastern shore of Lake Okeechobee in Southern Florida, where the growing season is long and winters are generally warm.

Who Controls Sugar in the U.S.?

Sugar is a commodity, which means its price is set in big international markets and is supposed to be pretty much the same all over the world. But in the U.S., the price has been greater than in other parts of the world, sometimes two or three times more. This significant markup is the result of U.S. laws and regulations.

The main policy tool the federal government uses to intervene in the market is called the U.S. Sugar Program, which began in 1934. It supplies cane and beet growers with subsidized loans, and limits imports through tariffs and by setting local selling quotas if imports fall below a certain floor.

The most influential and in many ways the main holding company in the U.S. is American Sugar Refining, Inc. (ASR), which is a partnership between the Fanjul family’s Florida Crystals and the Sugar Cane Growers Cooperative of Florida. ASR controls refineries by ownership or shareholder status in four states and six countries.

Does The U.S. Export Sugar?

While the United States does export on an annual basis, the nation is by far more reliant on imports since the start of the 21st century. The combination of unrestricted access to the US market, increases in Mexican production, and reductions in Mexican consumption will result in Mexico being a major supplier of sugar to the United States as the years go on.

There is a huge market for Brazilian imports of sugar across the world.